Globe valves are used to control flow of liquid in pipelines. You can allow or completely prevent flow of the fluid, or even adjust the amount of fluid that needs to pass. Basically, it adjusts the flow of liquid by moving up and down with the disc inside. Even though their usage purposes are different, we will discuss these valves, which have the same operating logic in our article. After finishing this article, you will find the answers to these questions.

- What is a globe valve and how does it work?

- Advantages and Disadvantages of Globe Valve?

- Globe Valve vs. Gate Valve Comparison?

- What kind of materials are they made of and where can we use them?

What is a Globe Valve ?

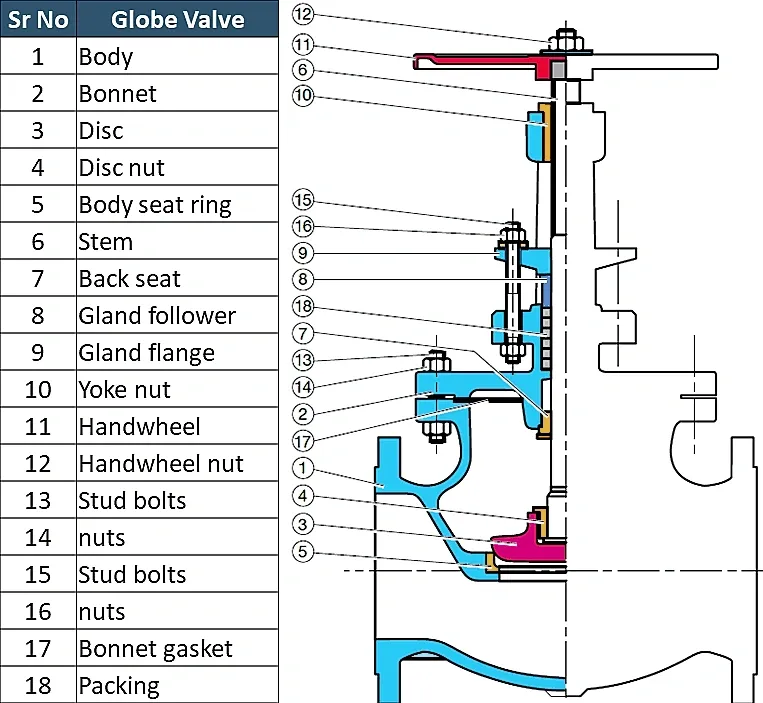

Globe valves basically consist of 4 main parts. These can be listed as Stem, Bonnet, Body, Disc/Plug. Let’s get to know these parts by looking at the picture above.

There is a disc at one end of the stem and a handle at the opposite side. We can adjust the position of valve with this Handle. Through teeth on the stem, if we turn the handle clockwise, it will start to move down and disc will sit on the valve seat. As a result, we stop the flow of fluid.

If we do the same process as counterclockwise, this time disc will move up and the fluid will be able to pass.

As you can see in the diagram, the flow direction can be in 2 different options.

Globe valves can be set up such that the disk shuts either in the opposite direction of the flow or in the same direction.

First Diagram

The fluid’s kinetic energy helps the disc / plug close in the flow direction but obstructs the opening. When a rapid halt is necessary, this attribute is preferred.

Second Diagram

When disc closes against the flow direction, fluid’s kinetic energy prevents the valve from shutting down, but it helps to open the valve. When a rapid start is required, this attribute is preferred.

Globe valve allows us to control the fluid movement and performs 3 major tasks:

-

Stopping the flow: With this valve placed between the pipelines, you can stop the flow of fluid.

-

Starting the flow: It usually turns the valve counterclockwise to allow the fluid to pass.

-

Adjusting rate of flow: You can adjust the flow rate of the fluid. The generally recommended approach in such globe valves is to be fully open or fully closed. But know that there is such a use case.

General features

As someone who works on globe valves, I would like to tell you about some useful features.

Without need to disassemble pipeline, we can open the upper part and directly interfere with the disc. (But, if valve body is damaged, you must disassemble completely) It can be used in circuits passing oil, fuel, water and gas because of its strong sealing property. Less wear occurs due to its design. (As i experienced most of weared part is seat valve or disc itself) It can remain partially open or completely stop the transition.

Globe Valve Diagram

I tried to tell you a lot of information about globe valves. Now let’s look at the parts in a little more detail. Globe valves consist of many parts and each of these parts has a task. If you know a valve better, you can better intervene in an undesirable situation .

Different Type of Globe Valve Parts

Valve Body

All parts of the valve are mounted on the main body. In other words, it is an important element of the valve. The body part can be made of different materials such as cast iron, aluminum etc. It offers different characteristics according to the material from which it is made. For example, if you are going to use it on a water pipeline, make sure it is made of non-oxidizing material. Likewise, it should be decided according to the working pressure and working temperature.

Valve stem

The valve stem is a cylindrical metal alloy part on the valve. It allows us to manually open and close the valve. It has a handle on one end and a valve plug / disc on the other. Thanks to the teeth on it, the disc can move up and down when we rotate it. Although there are models with different angles, it is generally kept in the same axis with the flow of the liquid. Thus, the force we spend while turning the valve is minimal.

Useful information: In valves that are used continuously, there are usually gaps between the stem and the packing, these gaps may open over time and cause the fluid leakage.

Valve Gland Packing

It is a material placed to prevent the fluid in the valve from escaping to the outside. As you can see in the diagram, it is a part between the stem and the bonnet. It completely wraps the stem and prevents the liquid from leaking. This part should be renewed after each valve maintenance. Because over time, it gets crushed, hardens and loses its sealing property. If you search for this material in the form of gland packing kit on the internet, you will see that there are many products with different features.

Bonnet and Bonnet Gasket

This piece acts as a cover by passing over the valve body. The stem passes through this part. There is a gasket between the body and the bonnet to prevent fluid leakage. When we are going to do globe valve maintenance, we remove the bolts on the bonnet and we can intervene directly inside the valve.

Globe Valve vs Gate Valve

| Globe Valve | Gate Valve |

|---|---|

| Globe valves are good at regulating flow. | Even, you can regulate the flow ,it is not recommended. if you try to regulate flow with this type of valve, occurs noise and vibration. |

| You have a complete control on flow. | It should be used completely opened or closed. |

| It is designed for one direction flow. | It can be used for both directions. |

| It’s closure element loooks like a bulb because of it’s shape. | It’s closure element is a plate or disk. |

| It can be opened or closed easly under high pressures. | if you try open or close against high pressure, may leakage happens. |

| Happens bigger pressure drops on fluid flow. | We face lower pressure drops on gate valves. |

What is a globe valve ?

A globe valve is a type of control valve used to regulate the flow of liquids and gases in a pipeline. It features a movable disk-shaped component that controls the flow by adjusting the opening or closing of the valve body. Globe valves are often preferred for precise flow control, as the disk can be precisely positioned to regulate the flow. They are commonly used in applications where precise regulation is necessary, such as in boilers, fuel oil systems, and firefighting systems.

Where to use globe valves on ships ?

Globe valves are commonly used in ships for controlling the flow of liquids, such as oil, water, or steam. They are typically used in applications that require precise regulation of flow, such as in piping systems for boilers, heat exchangers, and fuel oil systems. Globe valves are also used in firefighting systems, air conditioning systems, and lubricating oil systems. The location and number of globe valves on a ship will depend on the specific needs and design of the ship.