The most basic function of nitrogen generator systems is to separate nitrogen molecules in the air. The nitrogen obtained later can be used in different areas depending on the systems you use. These systems, which are generally used with air compressors, can be of different types. While preparing this content, we have taken the nitrogen systems used in ship systems as a basis, but we are sure that you can learn useful information regardless of the sector.

Nitrogen (N2) Generation Process

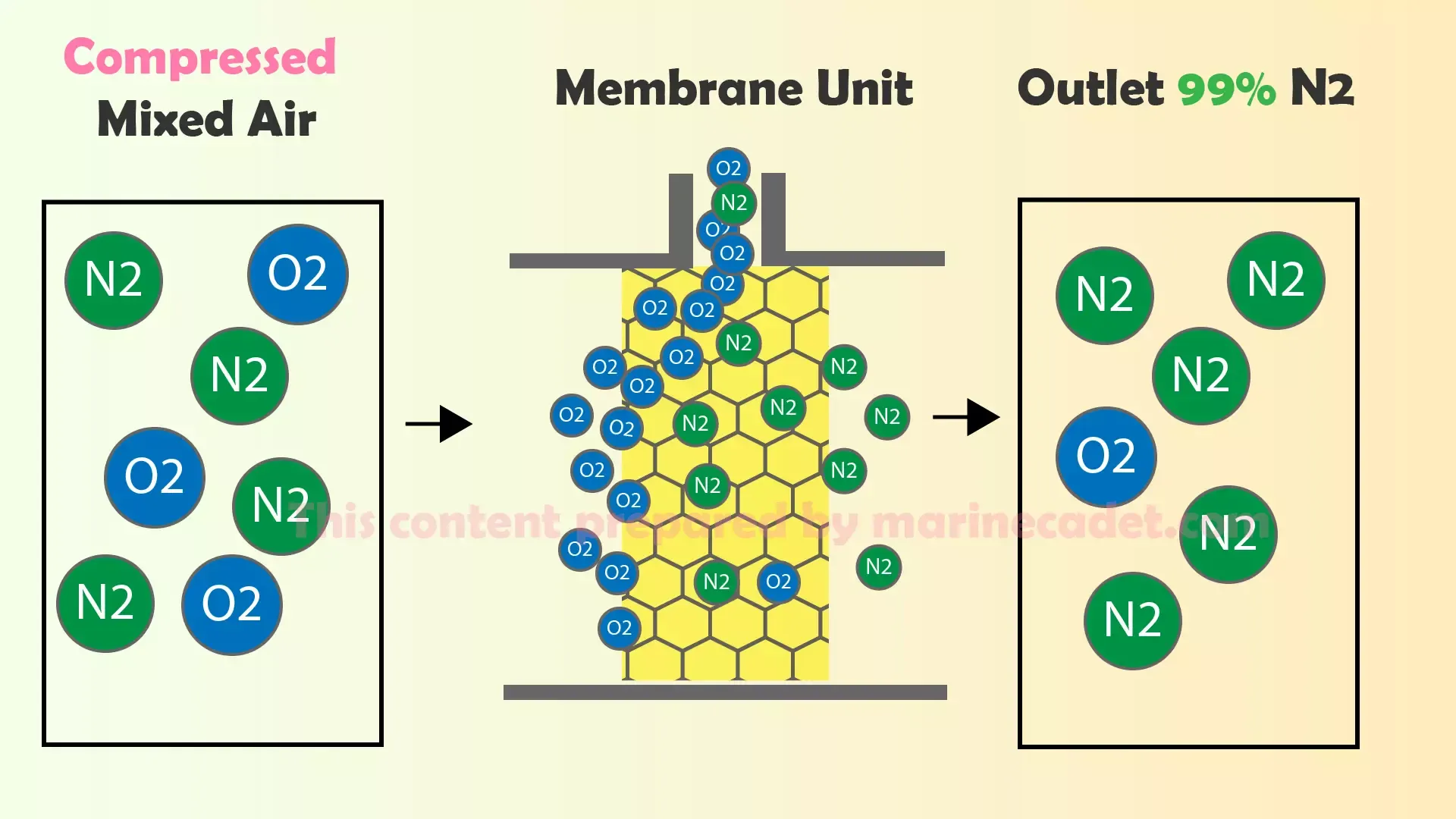

The working logic of nitrogen generators is quite simple. Think of a filter, we send compressed air to this filter. The filters we call membranes are made of polymer fibers. Nitrogen and argon molecules pass through more slowly than water and oxygen molecules in the air.

Thus, nitrogen and argon gases stay in the membrane for a longer time and separation is achieved. These separated gases are sent to different outlets, we only get nitrogen(N2). These generators are of 2 types, Membrane Nitrogen Generators and Pressure Swing Adsorption PSA Nitrogen Generators.

Membrane Type N2 Generator

These types of nitrogen generators basically work by passing air directly through the membrane. Nitrogen molecules in the air are sent to a different outlet by passing through the membrane, while unwanted oxygen and water molecules go to the atmosphere.

Let’s pay attention to this diagram.

We know that oxygen and water molecules have the property of permeating rapidly. How come the Nitrogen gets to the other side and the Oxygen is thrown out of the system?

The percolation properties of the substances are different. Nitrogen and argon move slowly when they enter the membrane, but oxygen and water move fast. So if there is a hole for the exit, the first water and oxygen will escape from there. Doesn’t it make sense 🙂 The continuous incoming compressed air will take the nitrogen molecules towards the desired exit. In fact, we have answered why an air compressor is used.

Pressure Swing Adsorption (PSA) Type N2 Generator

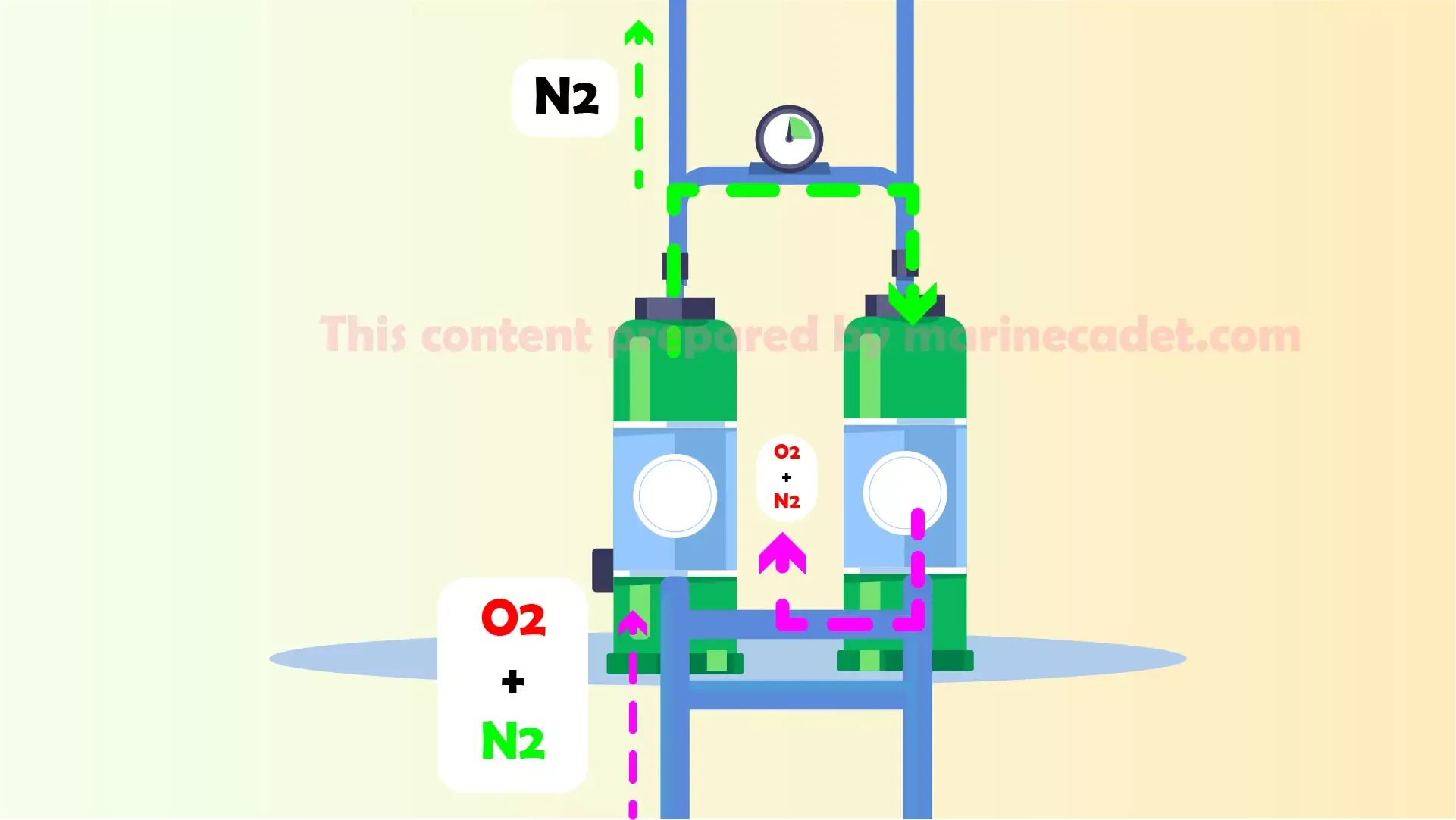

This type of nitrogen generators consists of 2 processes. Depending on the nitrogen(N2) purity you want, only the first stage or both are activated.

First Stage

Compressed air entering the first tank passes through an adsorbing material (such as a membrane), preventing the passage of most of the oxygen. Oxygen which cannot pass through the material, is sent to the atmosphere through an outlet pipe. Nitrogen molecules are sent to the 2nd stage or can be used directly.

Second Stage

There are generally computer-controlled valves on the system. These valves determine the direction of nitrogen. If the desired nitrogen purity is too high, the 2nd tank also comes into play. The same filtering process in the 1st stage is done here as well. As a result, nitrogen will be purer because it passes through the filter 2 times.

I think the system has become clearer in your mind. Now, I would like to talk about the detailed features of these two systems and the different parts used in the system for a better education.

Nitrogen Generator

Nitrogen generators are especially used in chemical oil ships and tanker ships carrying some combustible cargo. The reason for this is to prevent the flammable material from flashing and exploding for any reason. It doesn’t just have to explode, we also know that some active substances react with oxygen and decompose. So these generators are generally on board for 2 reasons, our safety and the safety of the cargo.

We explained the working logic of the Nitrogen system, but that’s not all. There are many problems affecting the system. We can list them as humidity, temperature, oil etc.

Water Factor

In these systems, water is our biggest enemy. Because, due to the working logic of nitrogen generators, if too much water enters the membrane unit, the membranes may not work at all. Remember, membranes are quite expensive parts and no one wants to throw them away.

Therefore, a dryer or heater should be attached to nitrogen systems and the water in the air should be removed before it enters the membrane.

Oil Factor

Oil usually enters the air from the air compressor. The compressor has its own lubrication system so that it can work for a long time in hot temperatures. There is an oil separator in the compressor, the oil is captured here and sent back to the compressor. If the oil separator is not doing its job properly, oil can pass into the air. This oil then clogs the membranes.

Temperature

Temperature is something we actually want in membrane type generators. Because the heated air molecules vibrate and become more active. Thus when passing through the membrane. oxygen and nitrogen separates better.

We cannot say the same for PSA type generators because the materials used in these generators do not like heat. In systems using the PSA type, it may be necessary to reduce the air to a certain temperature before it enters the vessels( process tank). We recommend that you find these specific values in the manufacturer’s manuals.

Nitrogen Purity Nitrogen systems allow us to adjust nitrogen purity according to the user’s request. In most systems, we can set the degree of purity we want digitally. The most important factor you need to know while doing this is the output flow. If you want to obtain a high purity, the system outlet pressure will decrease.

Nitrogen Generator Parts

Air Compressor

The air compressor produces the compressed air necessary for the operation of the system. There are models with electric or diesel running. The compressed air reaches to high temperatures.

Membrane

These equipments not only produce nitrogen but also separate different molecules. These filters, which are made very tight for a good separation process, generally consist of polymer components. We also said that they are expensive equipment 🙂 We recommend that you keep the system away from oil and water for a long working life.

Dryer

It is used to separate the water and moisture in the air. It is used in most nitrogen systems and not necessary to use. But if you are using a PSA type, you will see that it has a dryer.